EcoMak®

Why choose sustainable packaging materials?

PACKAGING AND CONSUMER PREFERENCES

There has been a monumental shift in the way consumers choose among products when standing in front of a supermarket shelf. Sustainability is increasingly becoming a major differentiating factor that allows some companies to stand out by catering to a consumer's desire to be ecologically sensible.

There has been a monumental shift in the way consumers choose among products when standing in front of a supermarket shelf. Sustainability is increasingly becoming a major differentiating factor that allows some companies to stand out by catering to a consumer's desire to be ecologically sensible.

By opting for a sustainable packaging structure, companies can adopt the consumer mindset and, therefore, brands can be better aligned with consumer needs. Needless to say, this translates to increased product differentiation and brand loyalty.

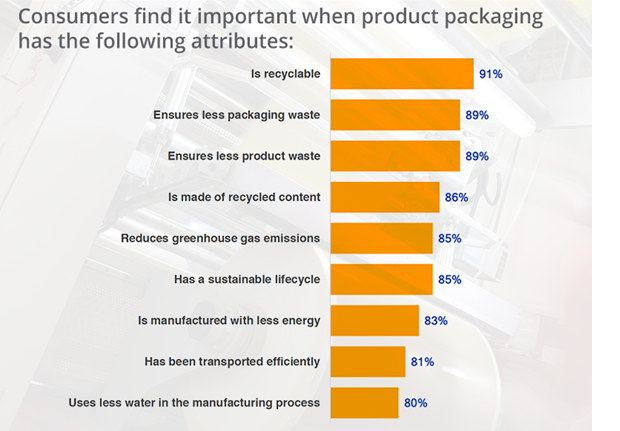

Currently, recyclability seems to be the main consumer concern, while other packaging attributes such as Greenhouse Gas (GHG) emissions, rank or transportation efficiency lower due to the limited customer perception in regards to the total product lifecycle, giving rise to the 'Packaging Paradox'.

THE PACKAGING PARADOX

A simplistic but popular perspective on packaging would suggest that less packaging is always better. Taken to its logical conclusion, we might assume that less packaging means using fewer resources. However, one of the fundamental functions of packaging is to protect precious resources. A delicate balance must therefore be struck between the amount of resources invested in packaging and the resources saved through the protection it provides. This is widely known as the 'Packaging Paradox': If we use an excessive amount of materials, this can lead to ‘overinvesting'; conversely, if we underinvest in packaging, we are at risk of wasting resources through the spoilage and wastage of the very contents we are trying to protect.

FLEXIBLE PACKAGING AND SUSTAINABILITY

Flexible packaging offers the perfect fit solution to the sustainability challenges of today. Flexible packaging simultaneously enables both the optimisation of packaging functionality and the best use of resources. This has the potential to provide considerable economic, environmental and social benefits making it the only real choice when sustainability is concerned.

Flexible packaging:

• Minimizes the product-to-package ratio due to its diverse morphology potential;

• Protects the enclosed product from external factors (O2, moisture, light, smells, etc.);

• Requires minimal resources and energy, thus emitting minimal greenhouse gases throughout its lifetime;

• Weighs considerably less than any packaging alternative;

• Has the lowest carbon footprint per unit throughout the supply chain;

…and many more!

However, due to the nature of plastic and its wide use, flexible packaging has been victimized, even though it offers a simple and adaptable answer to portioning, preservation and demands for convenience.

How we go about developing sustainable packaging structures?

OUR VISION

OUR VISION

Plastimak® has committed itself to being a sustainable and future-oriented supplier of flexible packaging material by integrating a long-term approach towards environmental protection and sustainability.

EcoMak® represents the company’s shift in focus towards the pursuit of an ecologically-responsible packaging philosophy for all its stakeholders, all the while maintaining the high performance and quality of Plastimak's products and services.

OUR APPROACH

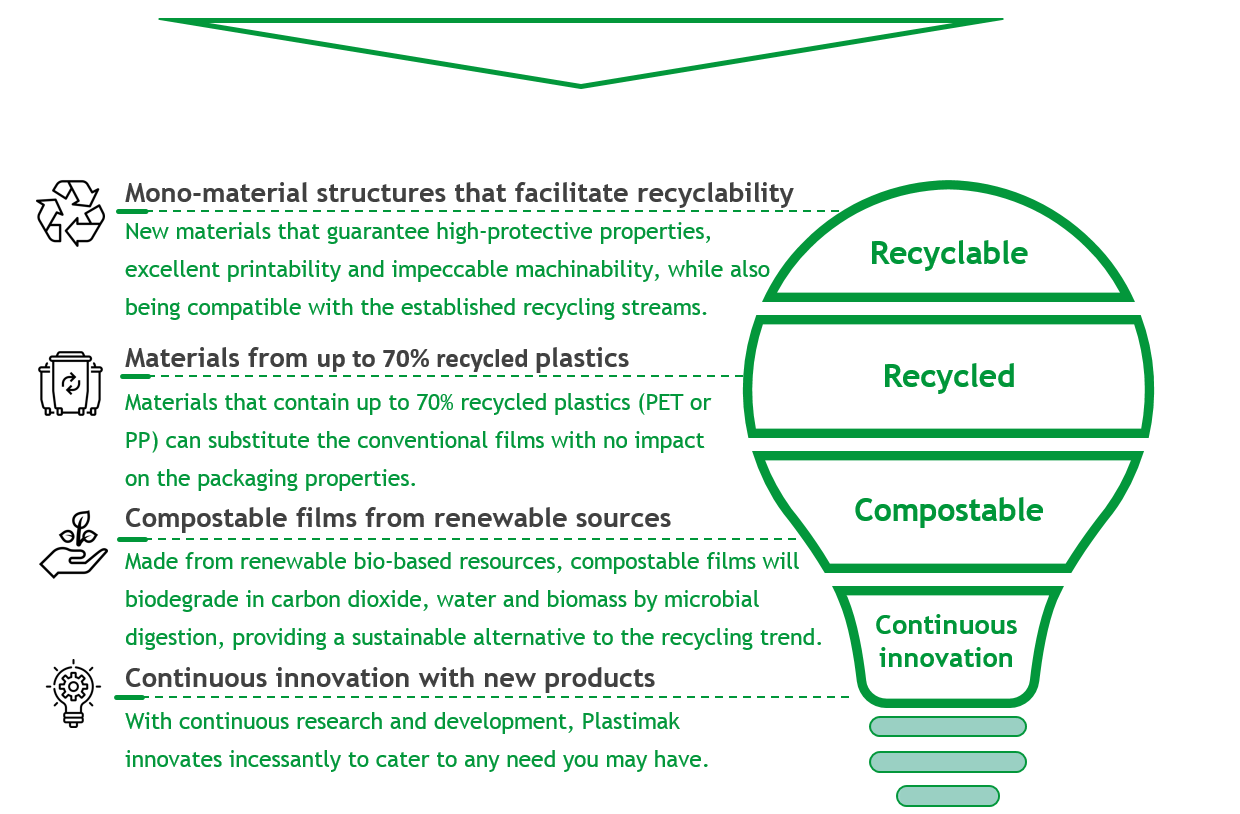

In order to eliminate the 'stigma' of flexible packaging and to better address the shift to the circular economy, Plastimak® has developed its EcoMak® line.

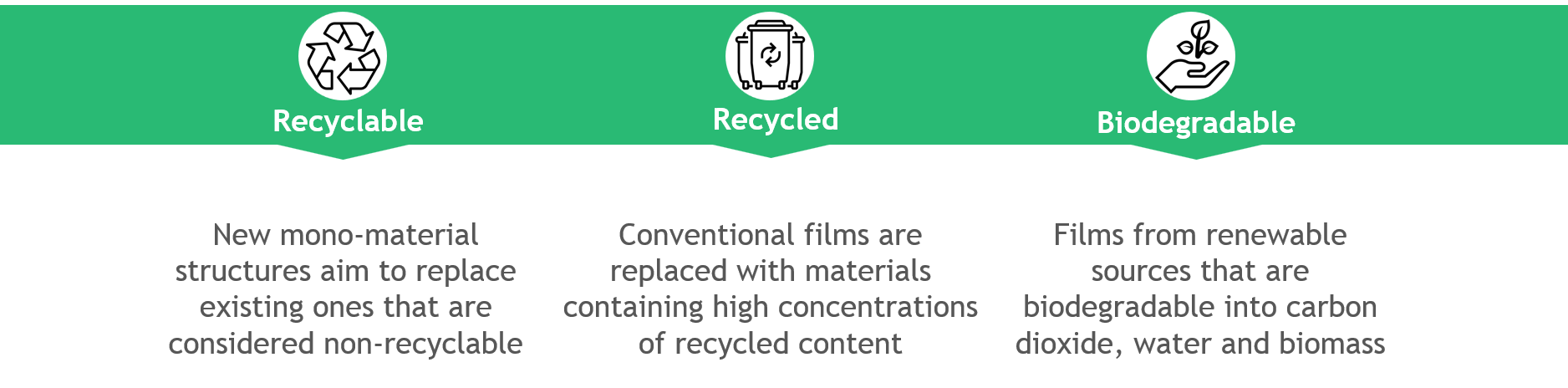

Consisting of three main streams: Recyclable, Recycled and Compostable, the EcoMak® line

offers the solution to any company aiming to become more sustainable. In developing those

solutions, we are characterized by an obsessive focus on Research and Development of

sustainable alternatives:

• We perform continuous testing of new materials to substitute non-recyclable structures;

• We put great emphasis on the increase of packaging resource efficiency through material and energy savings;

• Our products show zero compromise on product performance and shelf appeal;

• High definition printing ensures our products stand out when on the shelf;

• EcoMak® products are fully compatible with all bag morphologies, zippers and valves, enhancing customer utility;

• We develop new product structures that enhance product shelf life, thus reducing food waste;

• High Functional barriers ensure that humidity and oxygen stay out, while the aroma remains intact within the packaging.

HOW WE CAN HELP YOUR COMPANY?

Recyclable Stream

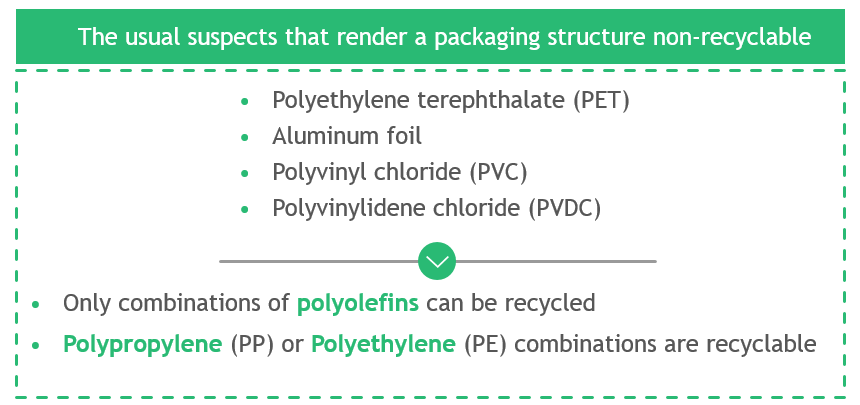

Under the current recycling infrastructure, multi-material flexible films, designed as such to provide a plethora of protective and functional properties, are not recyclable. The Recyclable Stream under the EcoMak® line ensures that all those conventional multi-material structures can be substituted with mono-material structures that offer the same, if not better, protective and functional properties.

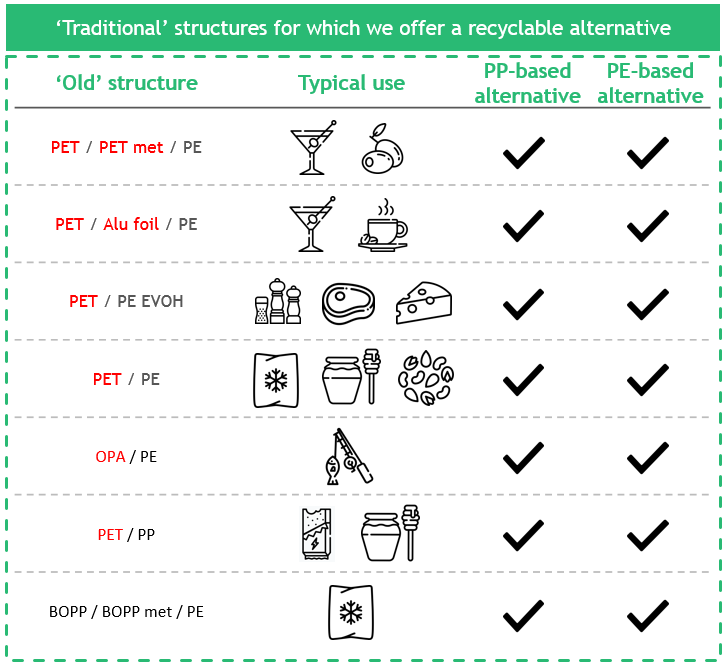

Currently, under the EcoMak® line you can find substitutes for all the conventional multi-material structures, as shown further below (find with red the non-recyclable components). Evident is that PET and Aluminum is considered non-recyclable as per the current recycling technologies but can be replaced seamlessly with our EcoMak® materials: the substitute films can provide all the functional barriers and are available in all bag morphologies. Additionally, the PP-based structures can be enhanced with low temperature sealing properties to ease machinability upon customer request.

Recycled stream

Substituting existing films with materials containing large percentages (up to 70%) of chemically recycled film can provide companies with a quick and easy way to 'join' the circular economy. Such films have almost identical properties to their 'virgin' counterparts and, as a consequence, there is minimal need for compatibility tests. This saves precious time, since a first-mover advantage is crucial in such cases, and costs as well.

Compostable stream

Made from renewable sources based on starch, our EcoMak® Compostable stream includes films that are biodegradable under specific conditions into carbon dioxide, water and biomass by microbial digestion. Bearing two certifications, DIN EN 13432 for Compostable intermediates and AIB-VINÇOTTE Internationale (four-star certification) "OK biobased", our films ensure the minimization of the packaging footprint. Heat-sealability, high stiffness and excellent twist retention make our Compostable structures ideal for fresh produce, bakery products and sweets.

For a disambiguation of the terms compostable and biodegradable, please click here.

For the EcoMak® line leaflet, please click here.